PRODUCTS

Impregnated Bits

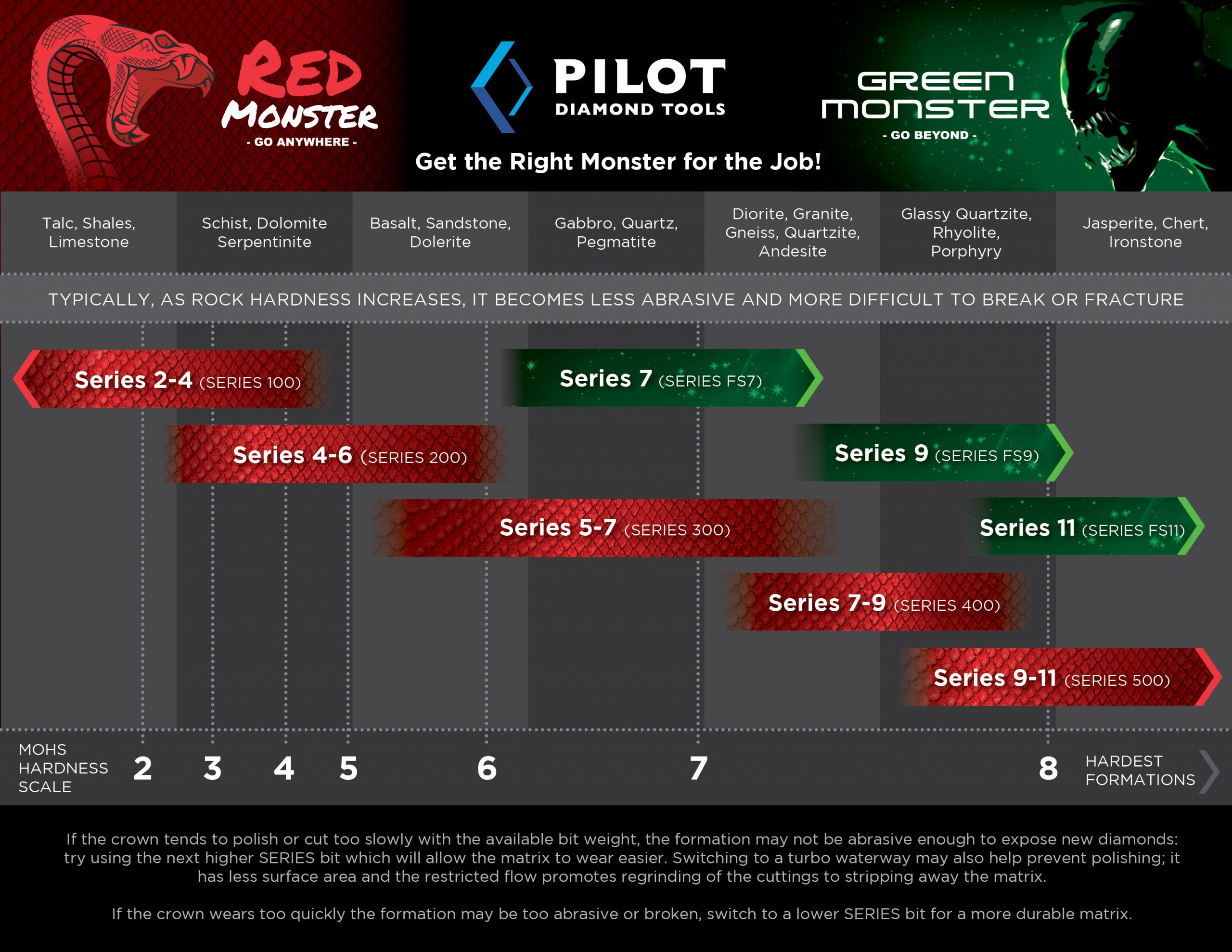

Decades of development have resulted in a consistent and reliable product making Pilot’s impregnated bits an excellent choice for your coring projects. We have looked at the overall drillability of the rock rather than concentrating only on hardness. By considering the combined effects of abrasiveness, hardness, and strength of the rock, Pilot has developed a series of five standard matrices and three focused matrices that will simplify and meet all your drilling challenges.

By its very nature, exploration takes on the unknown, so Pilot has eliminated the need to try to pick the right specialized product for a formation that has yet to be drilled. Instead, we listened to the concerns of the professional driller and, by giving careful thought to the metallurgical design, provided a small group of matrices which can perform well in a broad variety of conditions.

SECTION CHART

Red Monster Series

Red Monster is versatile enough to handle a broad range of Mohs hardness scale conditions to give you dependable performance from the beginning. Reach for a Red Monster first and Go Anywhere!

|

Series 2-4 (Series 100) |

Designed for the most broken and abrasive formations, where rock hardness is of secondary consideration. The SERIES 100 bit has a combination of matrix metallurgy and diamond selection that provides productivity while resisting premature wear from the formation. |

|

Series 4-6 (Series 200) |

This SERIES is for formations of medium abrasiveness and hardness, as in many sedimentary rocks and overburden conditions. Coarse-grained and fairly broken formations are the usual areas of application for this general purpose matrix. |

|

Series 5-7 (Series 300) |

A productive bit in medium to medium-hard formations, with moderate abrasion. The matrix is designed to provide sustained performance in most igneous rock formations and is a good starting point for those cases where the rock characteristics are unknown. |

|

Series 7-9 (Series 400) |

Finer grained rocks which offer little abrasive assistance to penetration need a freer-cutting matrix. This SERIES is the likely choice for the harder igneous and metamorphic formations, where there may still be some broken areas to pass through. Productivity is assured with this smooth-cutting matrix. |

|

Series 9-11 (Series 500) |

The least drillable, least abrasive and often hardest rocks present the greatest challenge to an impregnated bit because there is no natural mechanism for the matrix to erode, exposing fresh cutting surfaces. The SERIES 500 was developed to address this hurdle, allowing fresh diamonds to be presented without constant intervention from the driller. |

Green Monster Series

Use the Green Monster when you know the conditions and really want to dial-in the performance. Choose your best fit according to the Mohs Hardness scale. Our bit selection chart makes it easy!

|

Series 7 (Series FS7) |

This series of matrices forms a continuous range of solutions concentrating on the upper end of the rock hardness spectrum (6 and up), where a more focused product may be required, rather than a broadly tolerant range of application. Although there is some overlap of application between neighbouring members of the series, the driller should select the product closest to the expected geology shown in the Pilot application chart. This closely targeted range of products is easily matched and compared with the ranges from competing suppliers. |

|

Series 9 (Series FS9) |

|

|

Series 11 (Series F11) |

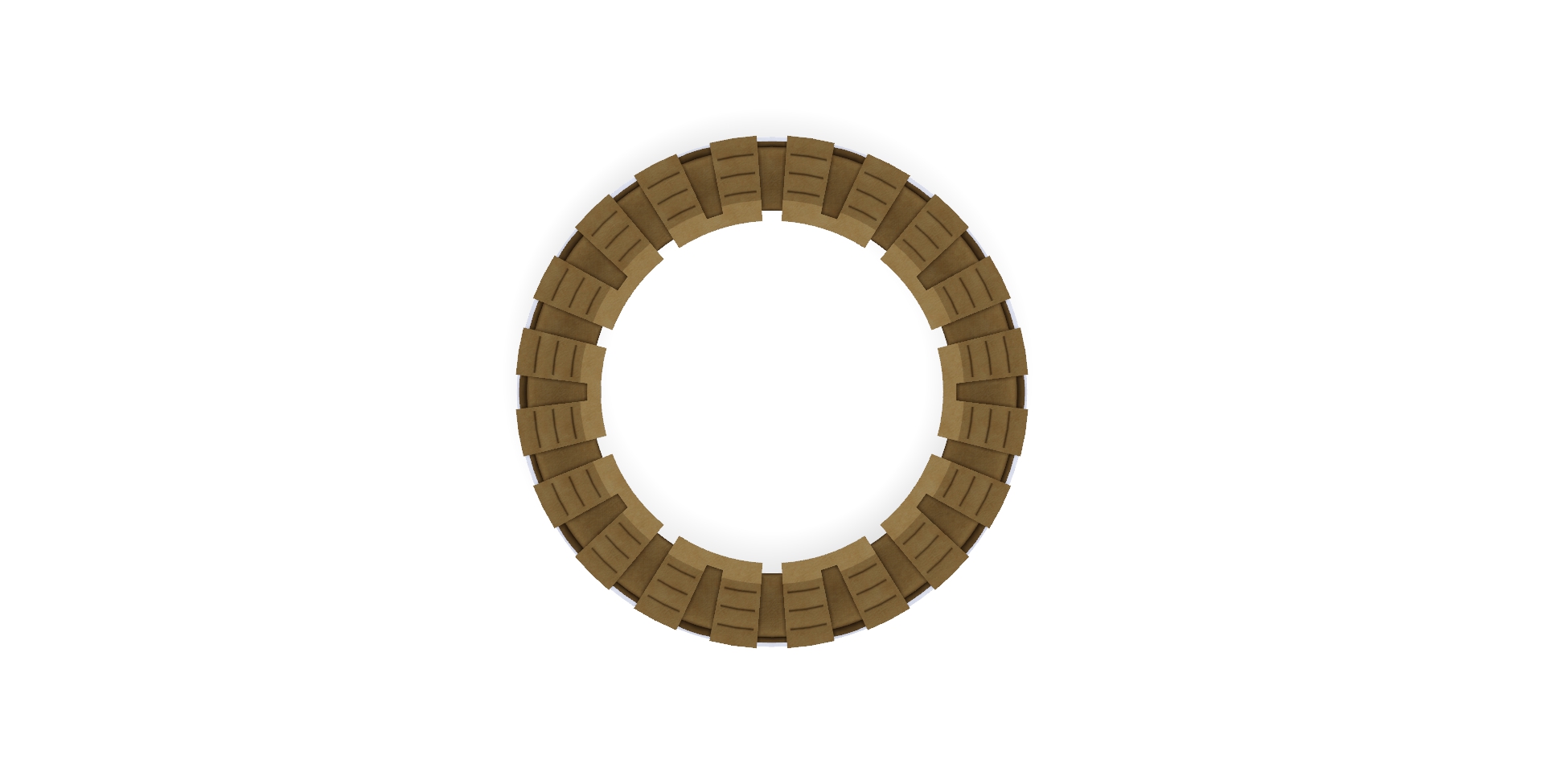

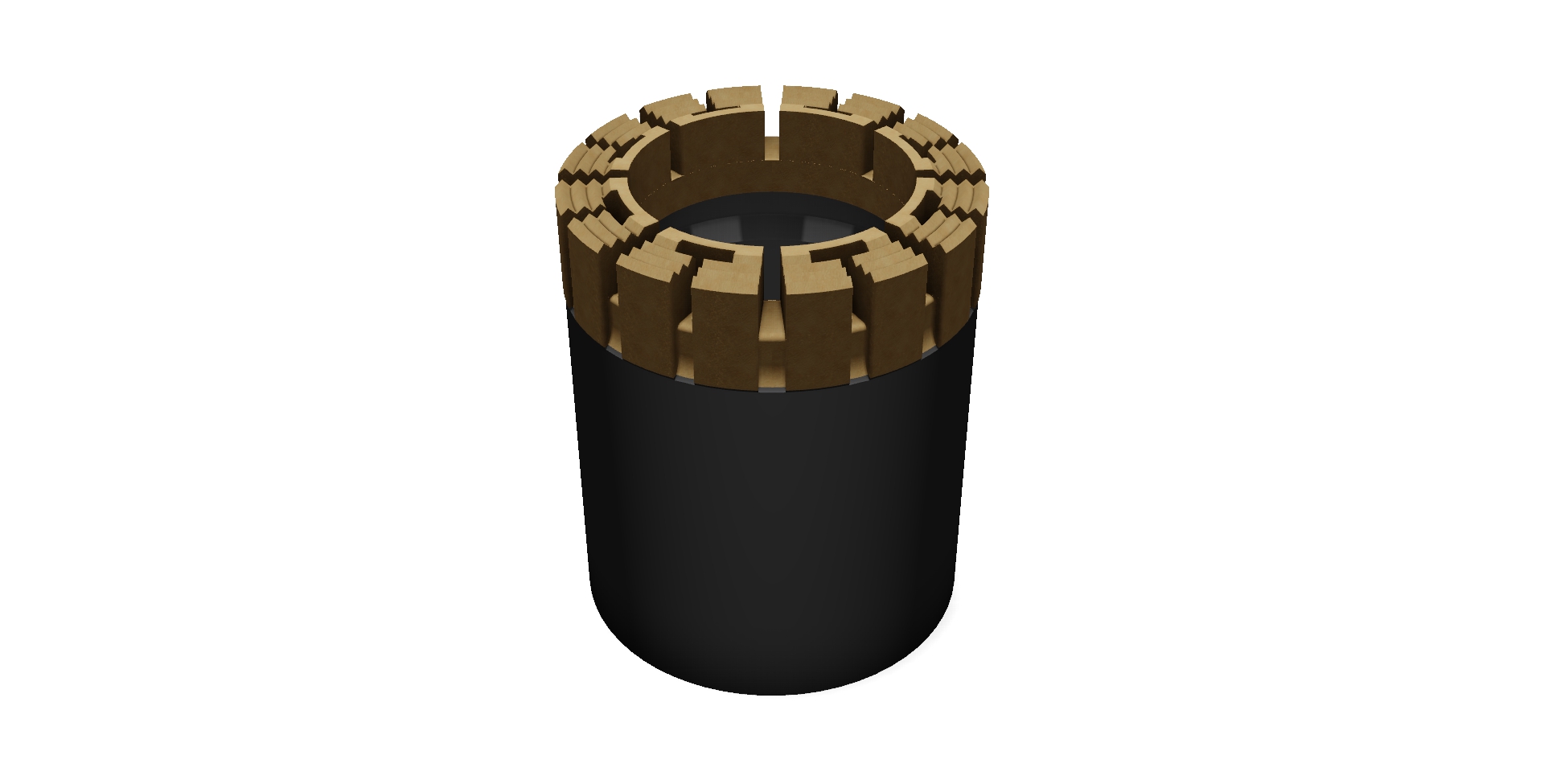

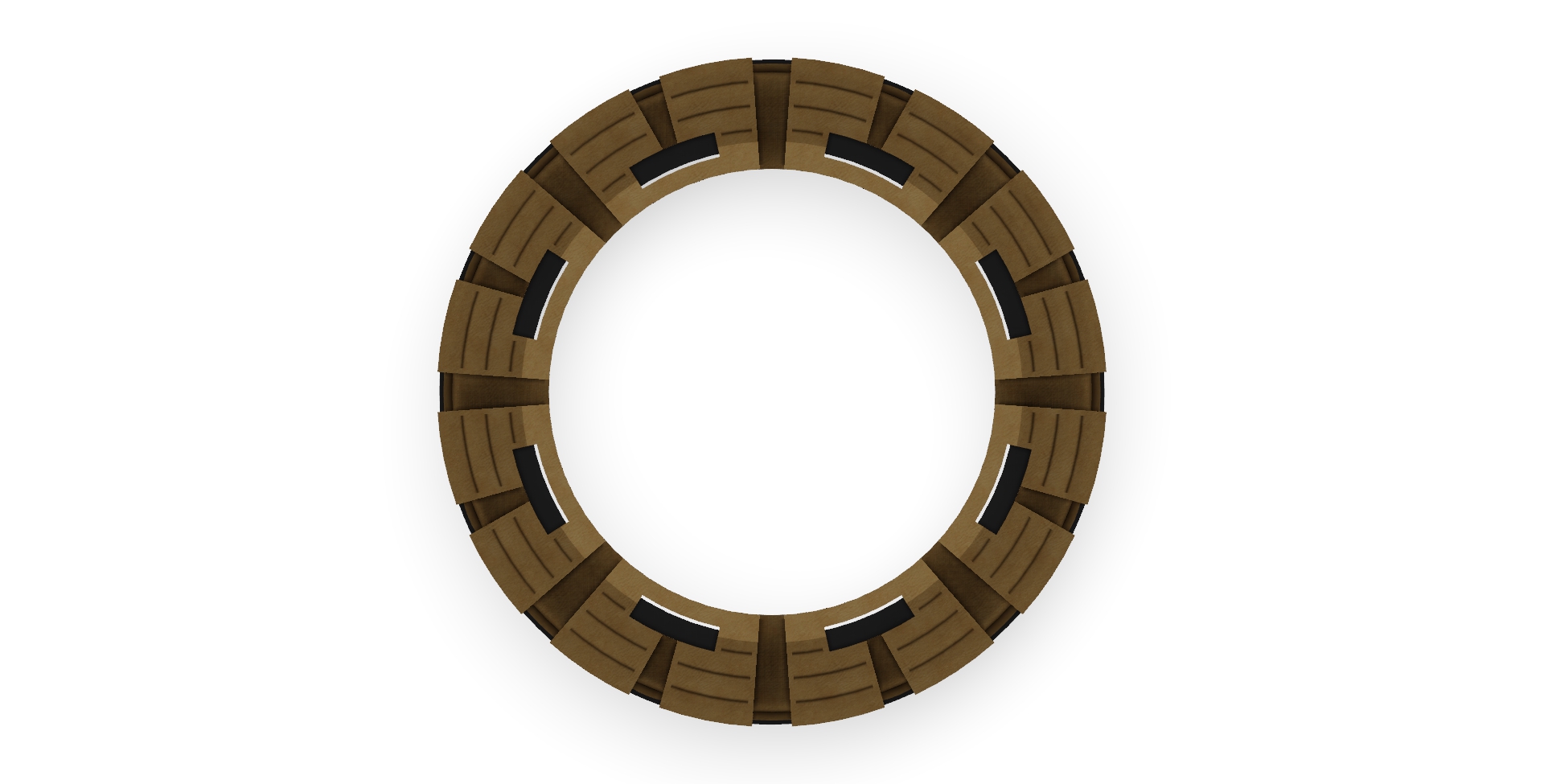

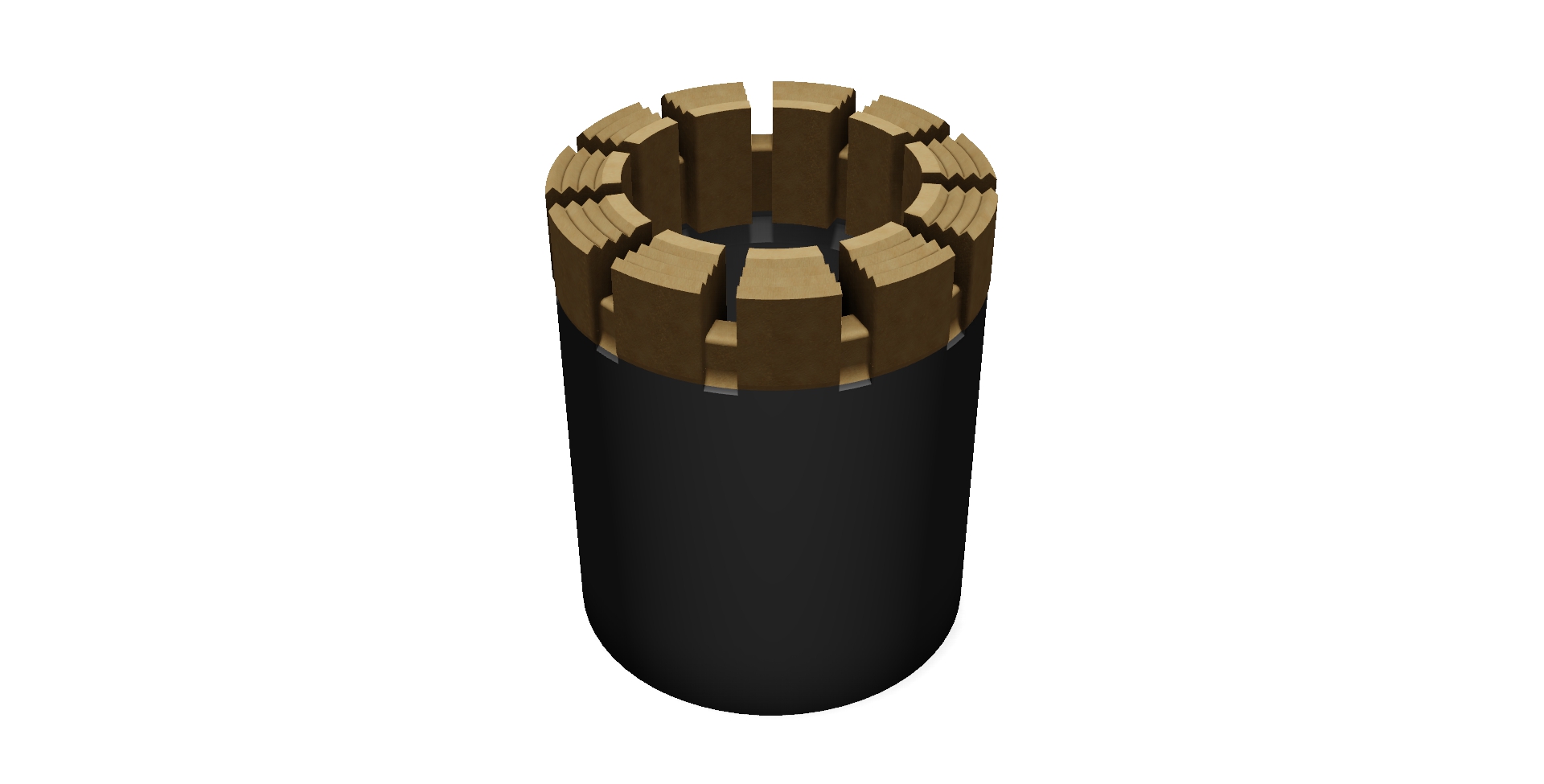

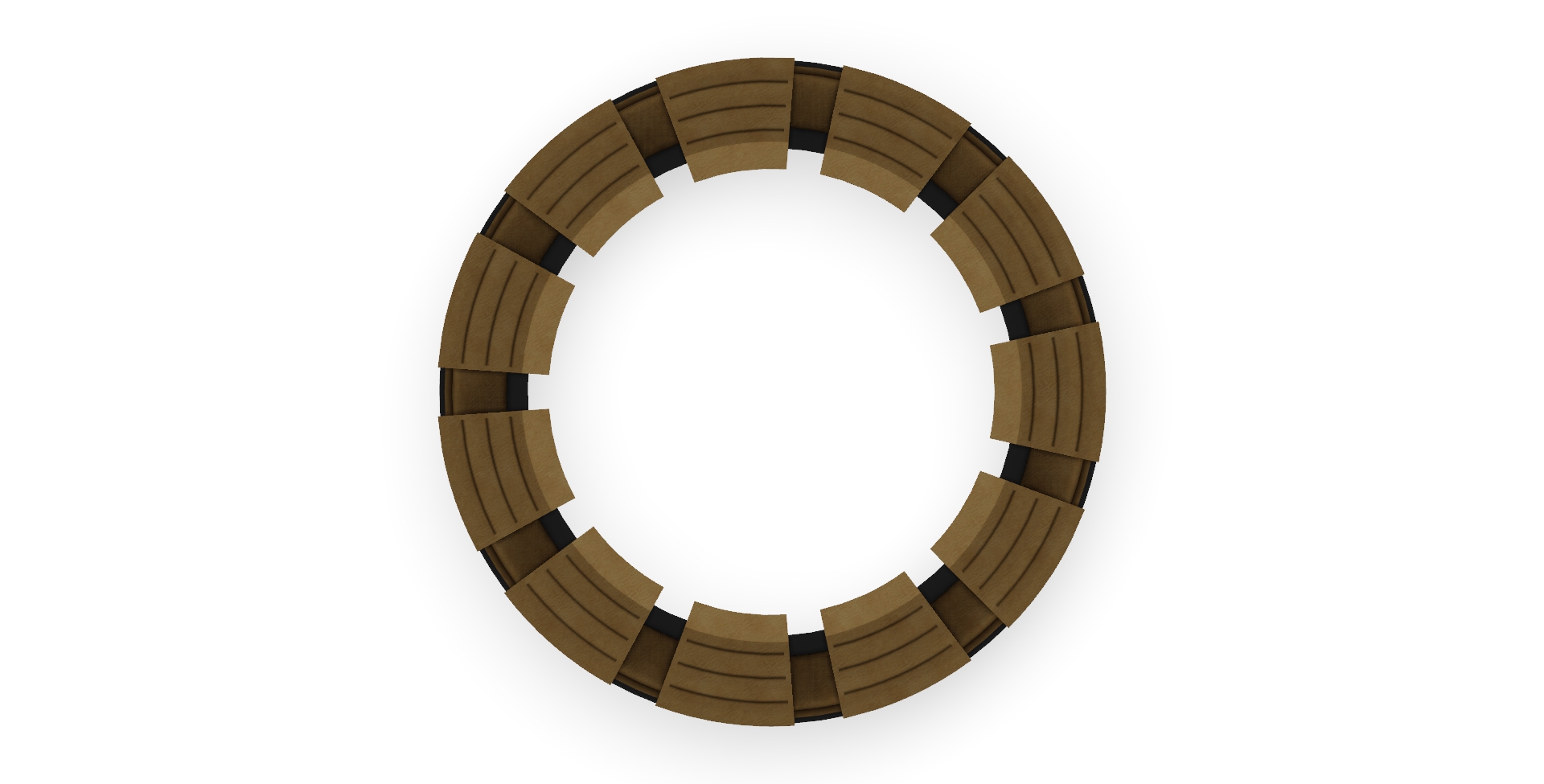

CROWN PROFILE

Productivity can only be truly maximized when the simple effect of pushing up the penetration rate is balanced by efficient flushing to prevent uneven wear and premature failure. By paying close attention to the hydraulic effects that take place at the bit face, Pilot has redesigned the following crown profiles to ensure maximum penetration, even at high rotational speeds.

Our waterways provide reinforcement where it is most needed, while minimizing the risk of unwanted deviation.

|

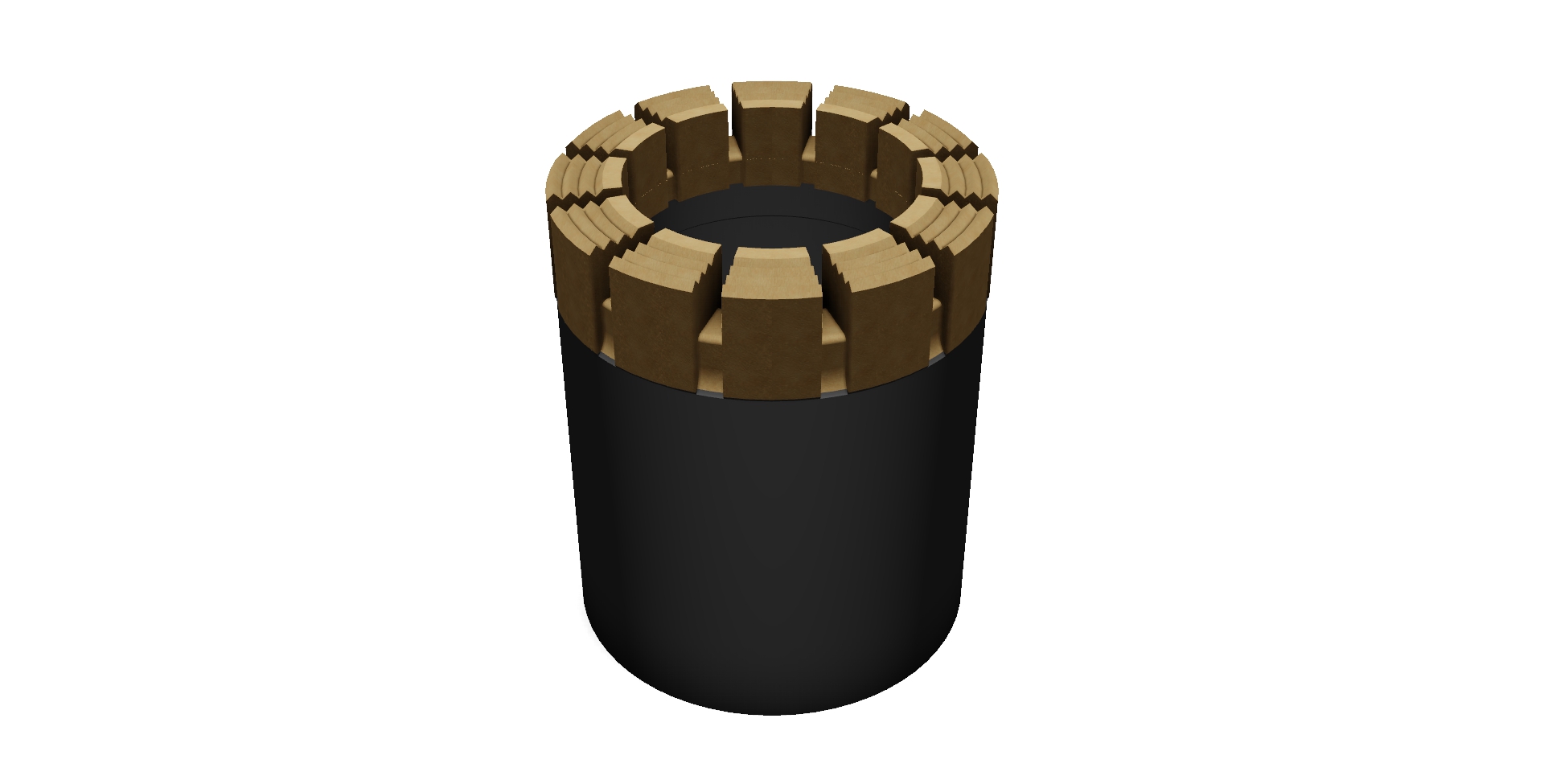

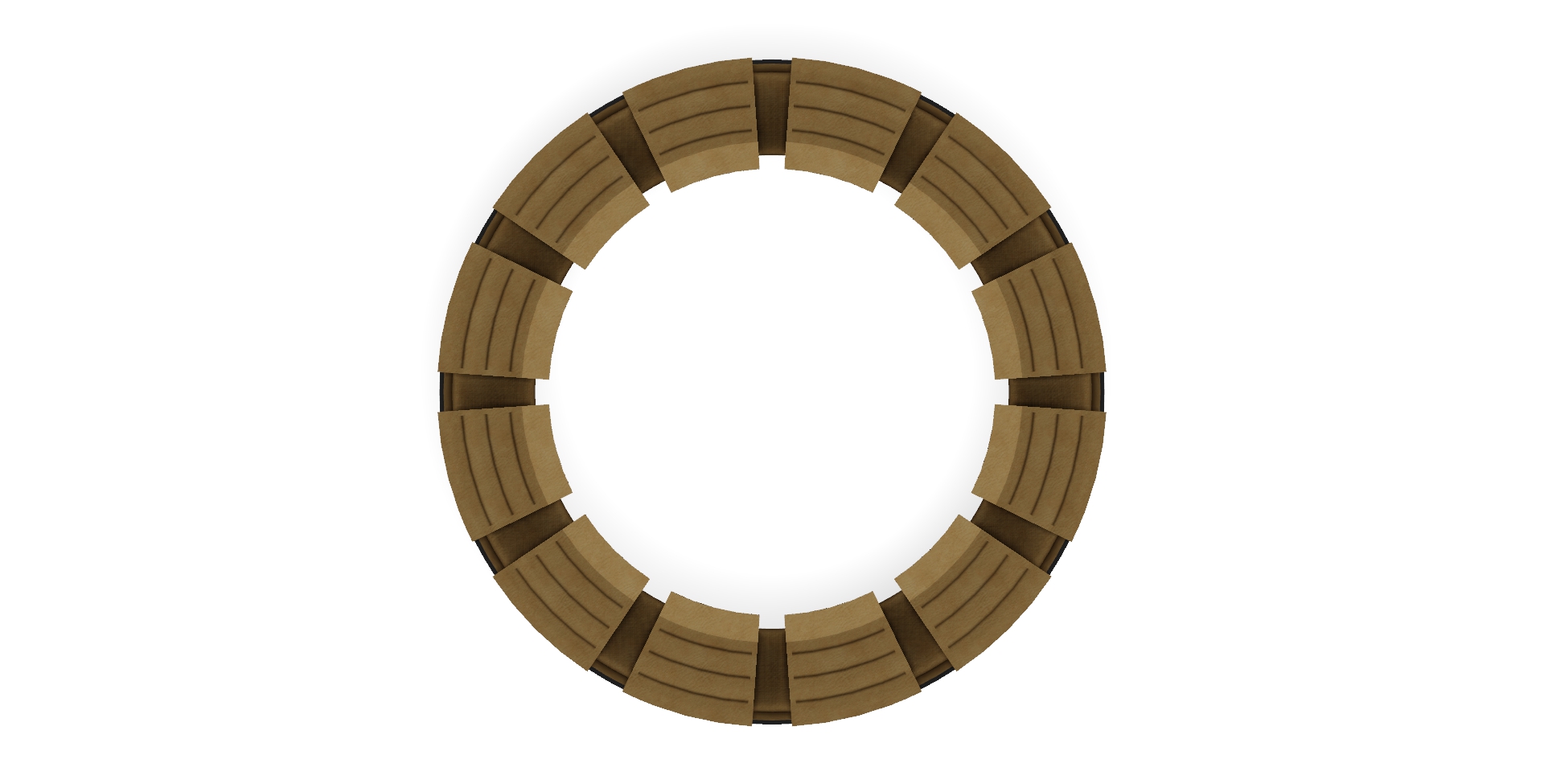

Standard crownThe waterway design and number of segments on the standard profile have been selected to provide a robust yet productive tool which can take on variable formations without seriously affecting performance. It is the default choice when facing the unexpected. |

|

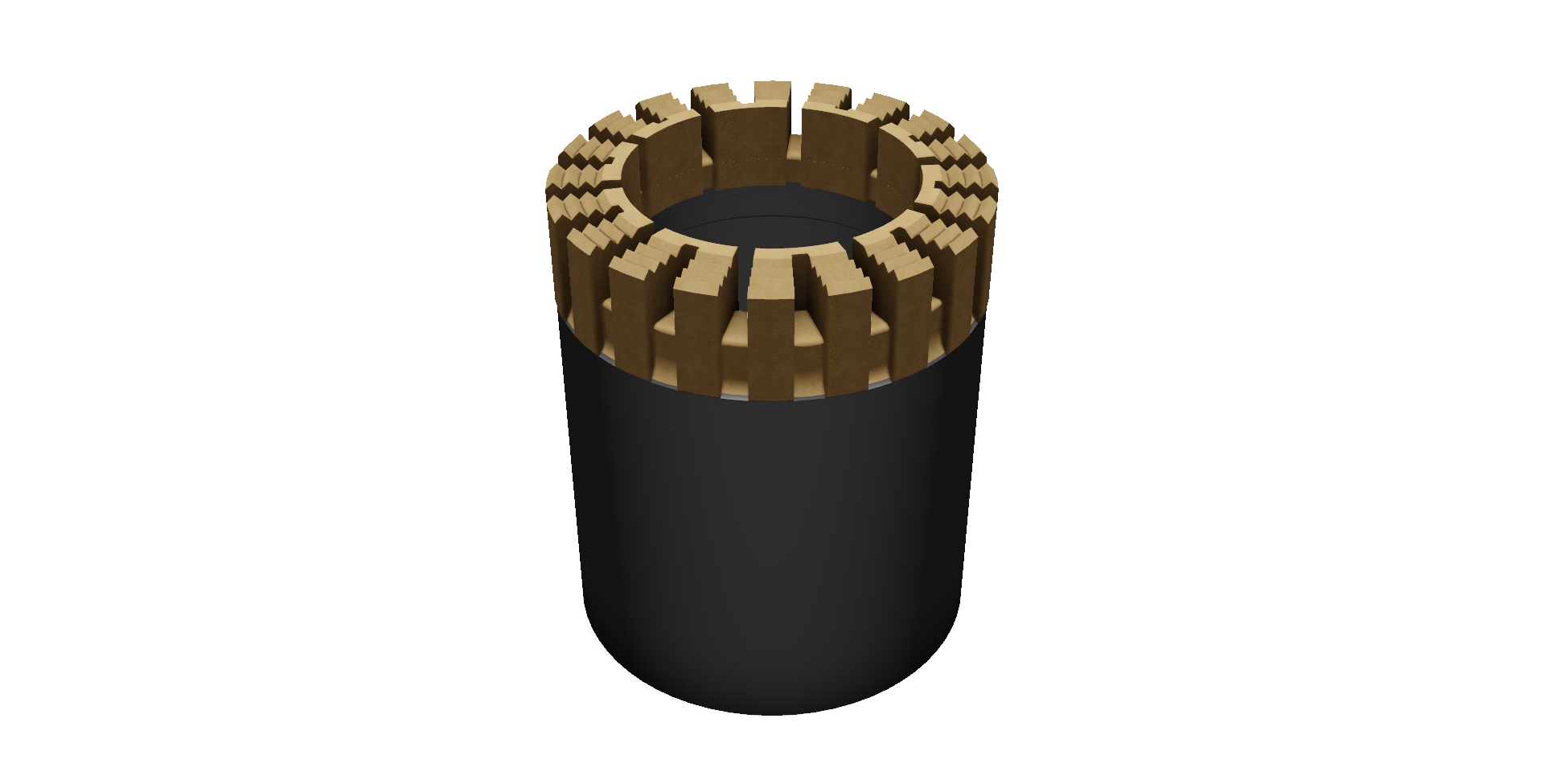

Turbo crownThis waterway stays effectively flushed and cooled even when higher rotational speeds are being applied, and the reduced face contact area permits the matrix to self sharpen more readily. Not recommended for unconsolidated formations. |

-Also available-

|

Face Discharge crownFor use in unconsolidated formations, where there is a chance that the drilling fluid could be lost to the formation without performing vital flushing. Pilot has taken a different approach from the conventional face discharge design, optimizing the chance of adequately clearing the cuttings while minimizing the chance of washing away the more fragile core. |

|

Deep IDSuitable for mixed formations. Slightly wider and deeper waterways allow more fluid to the face of the bit for better flushing without washing the core. |